The Materials

Not sure what you need?

Tell us your requirements and we’ll pick the perfect plastic!

Commodity

The plastic that started the consumer 3D-printing revolution. While not particularly strong, PLA is inexpensive, easy to print, and widely available, making it the perfect material for dimensional prototypes, decorative objects, and costume props.

A cousin of the familiar PET used to make soda bottles, PETG is a well-rounded intermediary material between PLA and the more durable engineering grade plastics.

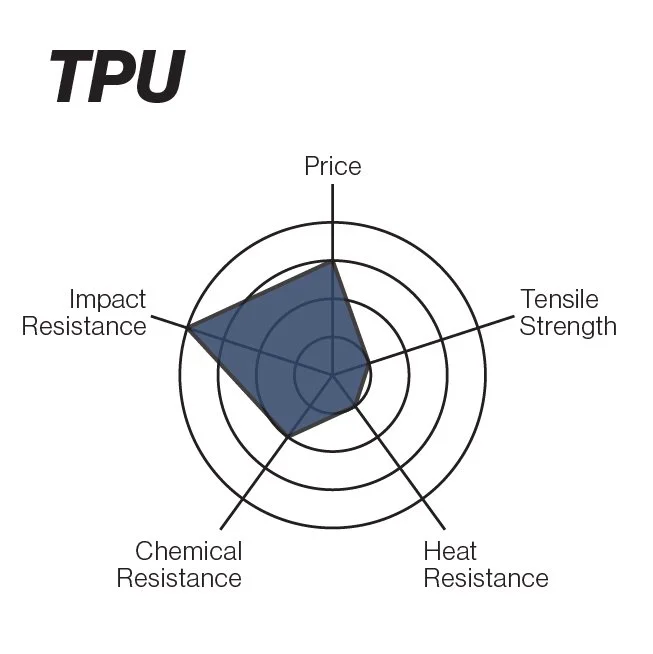

Did someone say flexible manufacturing? TPU (Thermoplastic PolyUrethane) is a truly flexible polyurethane rubber that can be used to print gaskets, grips, bumpers, and even a replacement for that rubber foot you lost off your air compressor.

Engineering

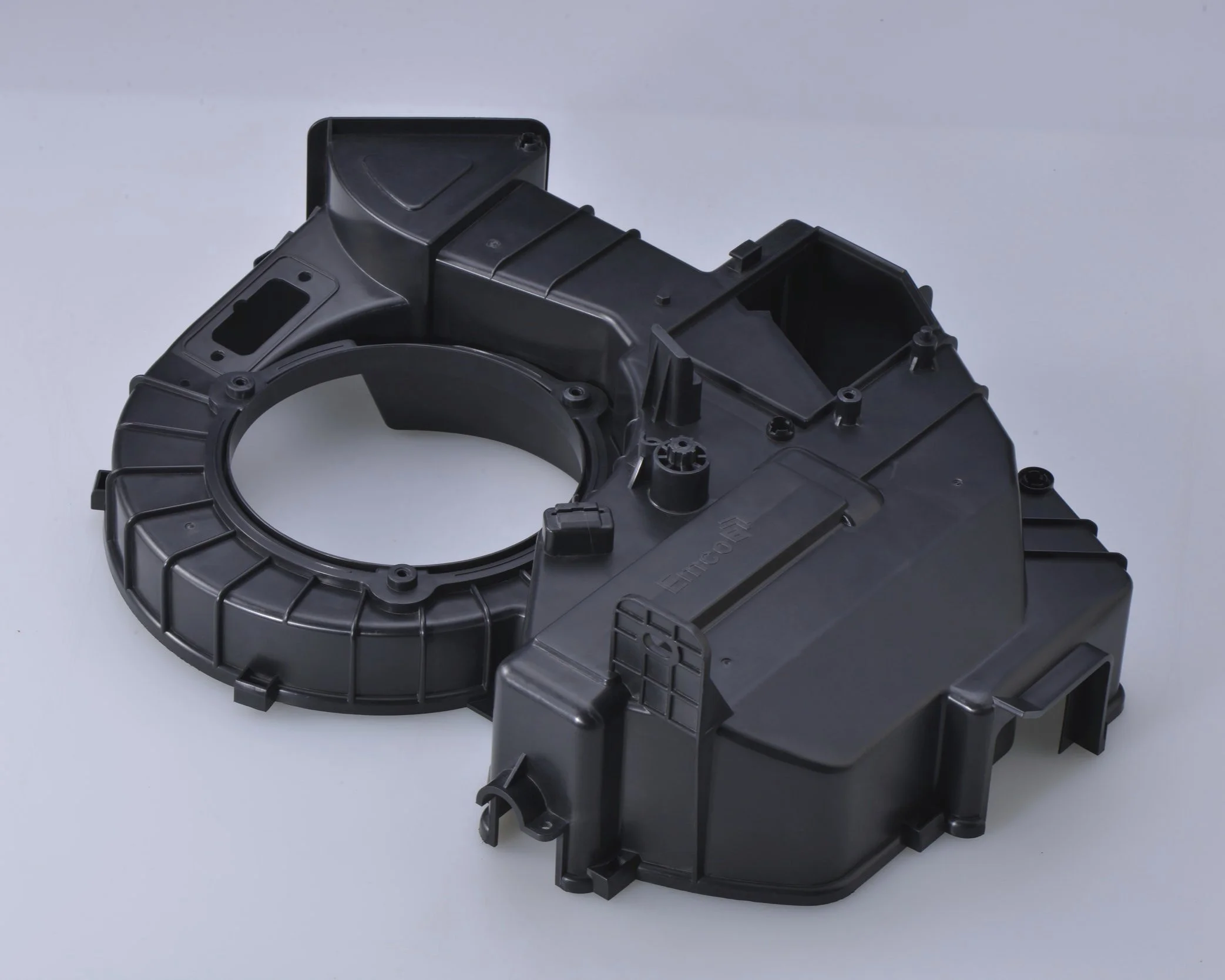

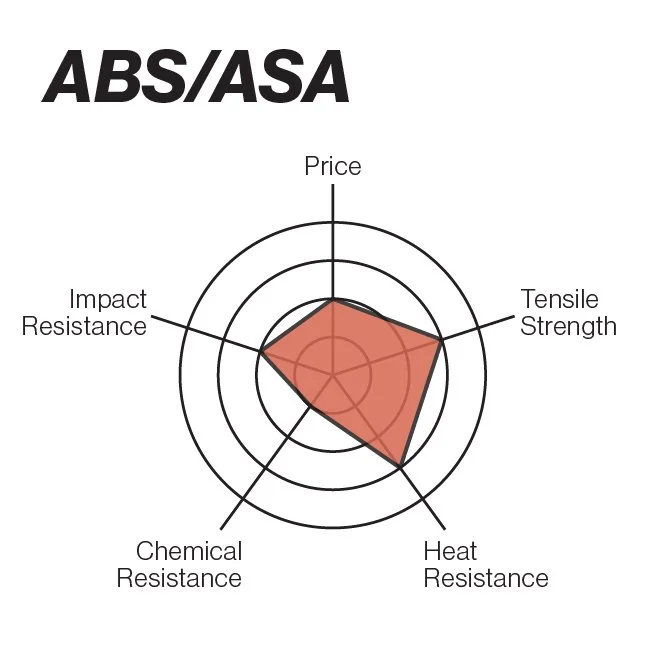

The most commonly used injection molding plastic, ABS/ASA is found in everything from automotive parts to childrens' toys, power tools to consumer electronics, and even furniture and appliances. If you want strength and durability without breaking the bank, look no further.

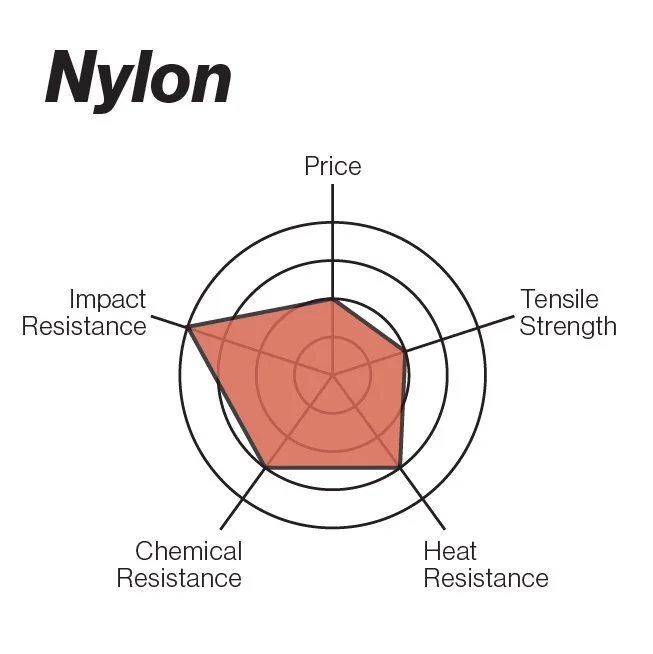

Durable, impact-resistant, self-lubricating, and broadly chemical resistant, Nylon is a go-to industrial plastic commonly used in moving assemblies, gears, and high-abrasion zones.

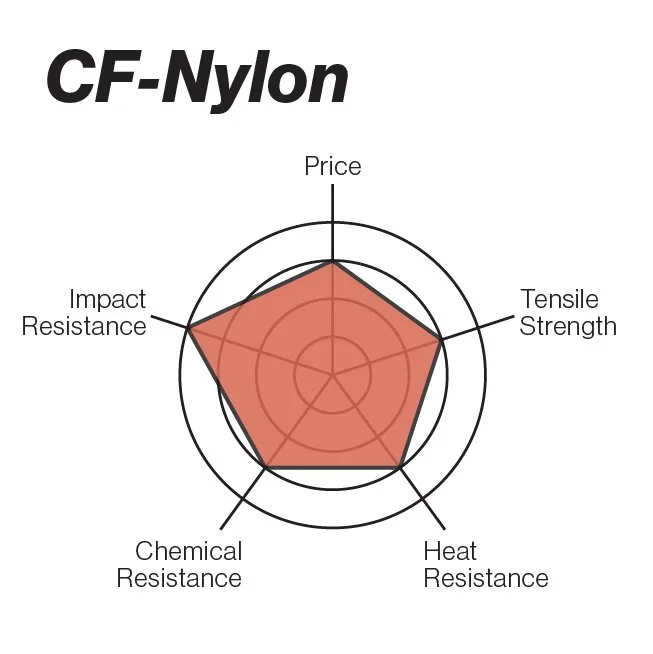

(Carbon Fiber filled Nylon) All the strengths of Nylon, with the added stiffness of carbon fiber. Dubbed "Black Aluminum", CF-Nylon provides a remarkably good aluminum analog without the incurring the pains of tooling or machining.

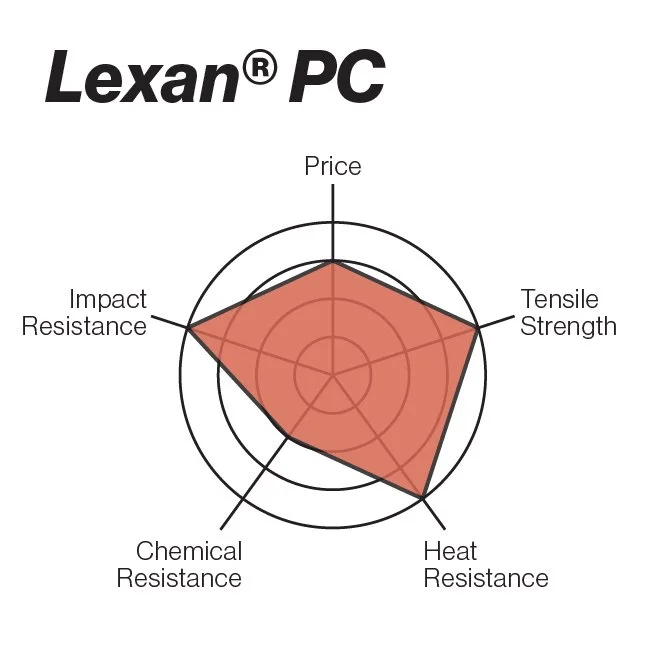

Familiar to most as the material of choice for bulletproof glass and riot shields, Polycarbonate offers nearly unmatched durability and respectable heat resistance with the unique option to be transparent.

Exotics

(PolyEtherEtherKetone) The king of polymers. One of the most thoroughly tested and certified plastics in the world; cleared for aerospace use due to its strength, broad chemical resistance, thermal stability, and UL94 V-0 flammability rating.

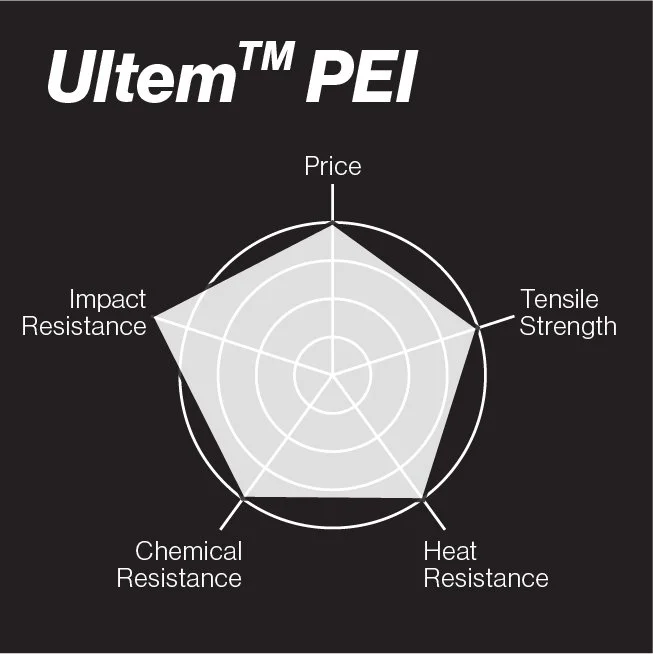

(PolyEtherImide) Think of it as PEEK's little brother. While similar in strength, chemical resistance, flame retardancy, and thermal stability to PEEK, PEI doesn't necessarily carry all of the same certifications. High performance at half the price.

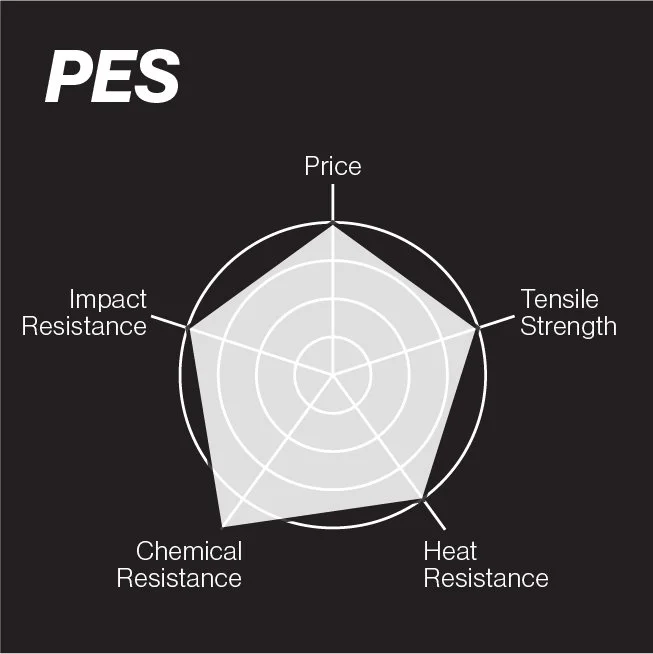

(PolyEtherSulfone) Another in the family of extreme performance PolyEther plastics, PES has remarkable thermal properties and near-perfect dimensional stability, making for excellent resistance to heat creep.